PRODUCT CENTER

2036 T6 round aluminum bar this is an early application of a kind of hard aluminum, commonly known as standard hard aluminum, with moderate strength, annealing, quenching and hot state plasticity is good, heat treatment can be strengthened, quenching and natural aging state in use, spot welding weldability is good. 2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃. The strength of 2036 alloy is higher than that of 7075 alloy. The formability is better in hot state, annealing state and new quenching state, and the effect of heat treatment is remarkable, but the heat treatment process is strict. Corrosion resistance is general, but with pure aluminum coating can be effectively protected, but using a special process can be welded, also can be riveted. Widely used in aircraft structures, rivets, truck wheels, propeller components and other structural parts.Mechanical properties

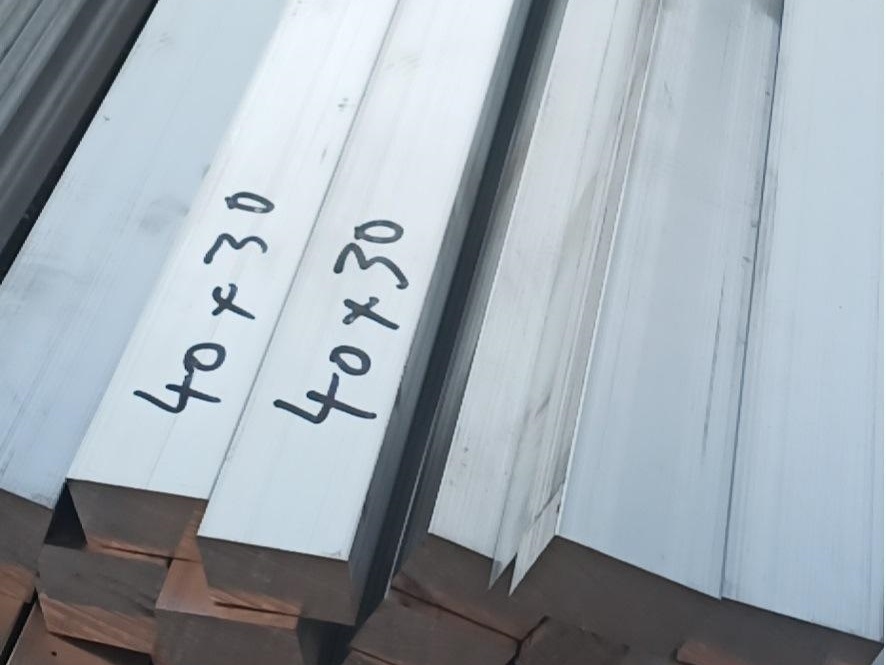

1050 H12 aluminum square bar Aluminum square bar is an aluminum rod with a square shape. Aluminum rod is a type of aluminum product, and the melting and casting process of aluminum rod includes melting, purification, impurity removal, degassing, slag removal, and casting.

1050 H112 trapezoidal aluminum bar

1050 H112 trapezoidal aluminum bar is an aluminum rod with a trapezoidal shape. Aluminum rod is a type of aluminum product, and the melting and casting process of aluminum rod includes melting, purification, impurity removal, degassing, slag removal, and casting. According to the different metal elements contained in aluminum rods, they can be roughly divided into 8 categories.

2A12 T6 round aluminum bar this is an early application of a kind of hard aluminum, commonly known as standard hard aluminum, with moderate strength, annealing, quenching and hot state plasticity is good, heat treatment can be strengthened, quenching and natural aging state in use, spot welding weldability is good. 2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃. The strength of 2036 alloy is higher than that of 7075 alloy. The formability is better in hot state, annealing state and new quenching state, and the effect of heat treatment is remarkable, but the heat treatment process is strict. Corrosion resistance is general, but with pure aluminum coating can be effectively protected, but using a special process can be welded, also can be riveted. Widely used in aircraft structures, rivets, truck wheels, propeller components and other structural parts.Mechanical properties

1100 H24 round aluminum bar is 99.0% ordinary industrial pure aluminum. Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance; After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained. 1100 aluminum alloy is formed by adding a small amount of copper element in pure aluminum, with excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. Widely used in products requiring good formability and high corrosion resistance, but not high strength requirements.

1080 H16 round aluminum bar is ordinary industrial pure aluminum. Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance; After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained. 1100 aluminum alloy is formed by adding a small amount of copper element in pure aluminum, with excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. Widely used in products requiring good formability and high corrosion resistance, but not high strength requirements.

1070 H16 round aluminum bar this is an early application of a kind of hard aluminum, commonly known as standard hard aluminum, with moderate strength, annealing, quenching and hot state plasticity is good, heat treatment can be strengthened, quenching and natural aging state in use, spot welding weldability is good.

1060 H14 round aluminum bar is divided into a variety of ways, high corrosion resistance, good weldability and electrical conductivity, tensile strength Ob (Mpa) 95 ~ 125 yield 0.2 (Mpa) > 75. 99.60% pure, high voltage wires are made of aluminum; In the food industry, from tanks to cans, and even beverage containers are mostly made of aluminum

1050 H12 round aluminum bar often used in daily necessities, lighting appliances, reflective panels, ornaments, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some requirements of corrosion resistance and formability are high occasions, but the strength requirements are not high, chemical equipment is its typical use.