PRODUCT CENTER

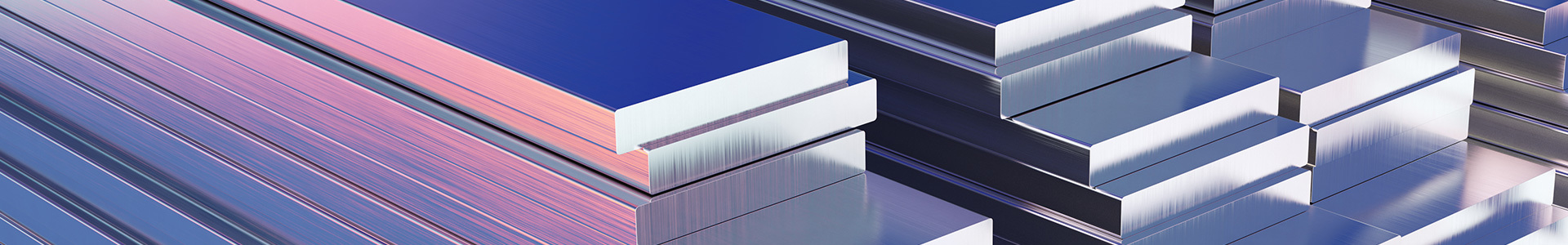

6061 T6 aluminum coil refers to the thickness of 0.4mm-2.5mm aluminum plate, we produce 6061 aluminum sheet, thickness up to 0.6mm, the aluminum plate has good oxidation effect, small deformation after processing, quenching effect is good, good stability can many advantages, in the mobile phone shell material, car hub, pull rod box, 3C products and other fields, enjoy a good reputation and reputation.

6063 T6 alloy aluminum coil is Al-Mg-Si high plastic alloy, with excellent machining properties, excellent weldability, extrusion and electroplating properties, good corrosion resistance, toughness, easy polishing, coating, anode oxidation effect is excellent.

6063 O alloy aluminum coil is Al-Mg-Si high plastic alloy, with excellent machining properties, excellent weldability, extrusion and electroplating properties, good corrosion resistance, toughness, easy polishing, coating, anode oxidation effect is excellent.

6061 O aluminum coil refers to the thickness of 0.4mm-2.5mm aluminum plate, we produce 6061 aluminum sheet, thickness up to 0.6mm, the aluminum plate has good oxidation effect, small deformation after processing, quenching effect is good, good stability can many advantages, in the mobile phone shell material, car hub, pull rod box, 3C products and other fields, enjoy a good reputation and reputation.

6005 T6 aluminum coil belongs to Al-Mg alloy, which is a kind of rust-proof aluminum widely used. This alloy is widely used, especially in the construction industry. It is a promising alloy, which cannot be strengthened by heat treatment and can be polished.

6060 aluminum alloy, American deformed aluminum and aluminum alloy. 6000 series aluminum alloy features: mainly magnesium and silicon. Mg2Si is the most widely used alloy as the main strengthening phase. Characteristics: Medium strength, good corrosion resistance, good welding performance, good process performance (easy extrusion forming) oxidation and coloring performance.

6082 T6 aluminum coil is a heat-treatable alloy, has good formability, weldability, machinability and corrosion resistance, at the same time has moderate strength, can still maintain good operation after annealing. Mainly used in transportation and structural engineering industry.

6082 O aluminum coil is a heat-treatable alloy, has good formability, weldability, machinability and corrosion resistance, at the same time has moderate strength, can still maintain good operation after annealing. Mainly used in transportation and structural engineering industry.

6060 aluminum alloy, American deformed aluminum and aluminum alloy. 6000 series aluminum alloy features: mainly magnesium and silicon. Mg2Si is the most widely used alloy as the main strengthening phase. Characteristics: Medium strength, good corrosion resistance, good welding performance, good process performance (easy extrusion forming) oxidation and coloring performance.

6005 O aluminum coil belongs to Al-Mg alloy, which is a kind of rust-proof aluminum widely used. This alloy is widely used, especially in the construction industry. It is a promising alloy, which cannot be strengthened by heat treatment and can be polished.