PRODUCT CENTER

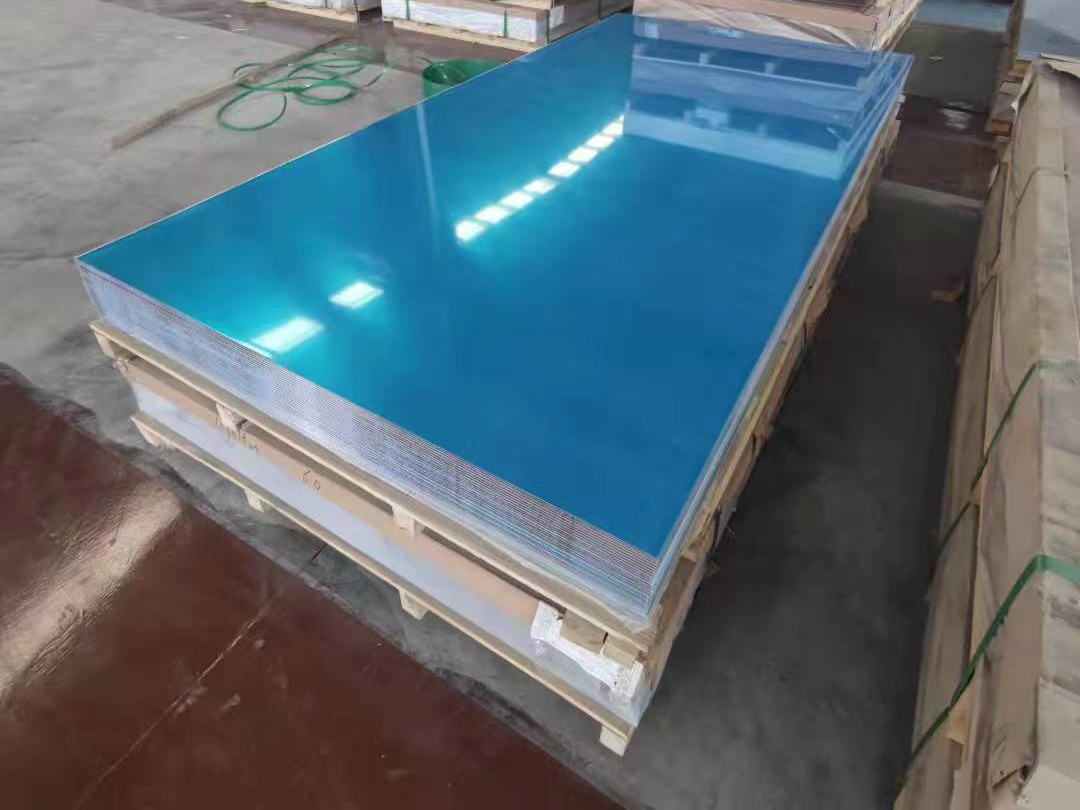

7005 T6 aluminum plate is super duralumin, good welding performance, heat treatment strengthening, strength is not as good as 6061 aluminum plate, but much lighter, typical lightweight aluminum. It is often used in welding structures with high strength and high fracture toughness, such as vehicle trusses, rods and containers. Large heat exchangers and parts that cannot be fused after welding; It can also be used to make sports equipment such as tennis rackets and softball bats.

The main alloy element of 7050 T6 aluminum plate is zinc. Adding magnesium to the alloy containing 3%-75% zinc can form MgZn2 with remarkable strengthening effect, so that the heat treatment effect of the alloy is much better than that of Al-zinc binary alloy. Mainly used for mold processing, mechanical equipment, fixture, etc., especially for high stress structure requiring high strength, strong corrosion resistance.

7075 T6 aluminum sheet is a cold treatment forged alloy with high strength, 7075 is one of the strongest commercially available alloys. General corrosion resistance, good mechanical properties and anode reaction. The fine grain makes the deep drilling performance better, the tool wear resistance is enhanced, and the thread rolling is different from the weight.

7A04 H112 aluminum plate belongs to Al-Zn-Mg-Cu series of ultra-high strength aluminum alloy, which is commonly used in ultra-duralumin. It is quite mature among ultra-duralumin, and is an alloy used for a long time and a wide range. It has high strength and good heat treatment strengthening effect.

7A04 T6 aluminum plate belongs to Al-Zn-Mg-Cu series of ultra-high strength aluminum alloy, which is commonly used in ultra-duralumin. It is quite mature among ultra-duralumin, and is an alloy used for a long time and a wide range. It has high strength and good heat treatment strengthening effect.

7075 O aluminum sheet is a cold treatment forged alloy with high strength, 7075 is one of the strongest commercially available alloys. General corrosion resistance, good mechanical properties and anode reaction. The fine grain makes the deep drilling performance better, the tool wear resistance is enhanced, and the thread rolling is different from the weight.

The main alloy element of 7050 O aluminum plate is zinc. Adding magnesium to the alloy containing 3%-75% zinc can form MgZn2 with remarkable strengthening effect, so that the heat treatment effect of the alloy is much better than that of Al-zinc binary alloy. Mainly used for mold processing, mechanical equipment, fixture, etc., especially for high stress structure requiring high strength, strong corrosion resistance.

7005 O aluminum plate is super duralumin, good welding performance, heat treatment strengthening, strength is not as good as 6061 aluminum plate, but much lighter, typical lightweight aluminum. It is often used in welding structures with high strength and high fracture toughness, such as vehicle trusses, rods and containers. Large heat exchangers and parts that cannot be fused after welding; It can also be used to make sports equipment such as tennis rackets and softball bats.