PRODUCT CENTER

1050 O Double glazed light aluminum foil

1050 O Double glazed light aluminum foil Double sided light aluminum foil: Single rolled aluminum foil, with both sides in contact with the roller. The two sides of the aluminum foil are divided into mirror faced double-sided glossy aluminum foil and ordinary double-sided glossy aluminum foil due to different surface roughness of the roller. The thickness of double-sided glossy aluminum foil is generally not less than 0.01mm.

1050 O Single glazed aluminum foil

1050 O Single glazed aluminum foil Single sided light aluminum foil: Double rolled aluminum foil, with one side shiny and one side black after being rolled. The thickness of single sided glossy aluminum foil usually does not exceed 0.025mm.Only one side of the single-sided aluminum foil can be used, while the other side is protected by insulation and cannot be used for other purposes, such as extension, chemical reaction, etc.Aluminum foil is mainly used in air conditioning, cigarette packaging, food packaging, electronic components, decoration and so on

1050 O Coated aluminum foil is to coat the dispersed nano-conductive graphite and carbon-coated particles evenly and finely on the aluminum foil/copper foil, so that it can provide excellent static electrical conductivity.

1050 O Aluminum foil box The thickness of aluminum foil boxes is generally between 0.03mm and 0.20mm, and can be divided into two types: wrinkled and wrinkle free. It can also be divided into two types: disposable and reusable. It is a production process that uses 3 series or 8 series aluminum ingots as raw materials, which are cold-rolled or hot-rolled to produce aluminum foil master rolls with uniform thickness, smooth surface, no pinholes, dust particles, and no odor. It is fully automatic cold stamping formed in one go through specialized equipment and molds.

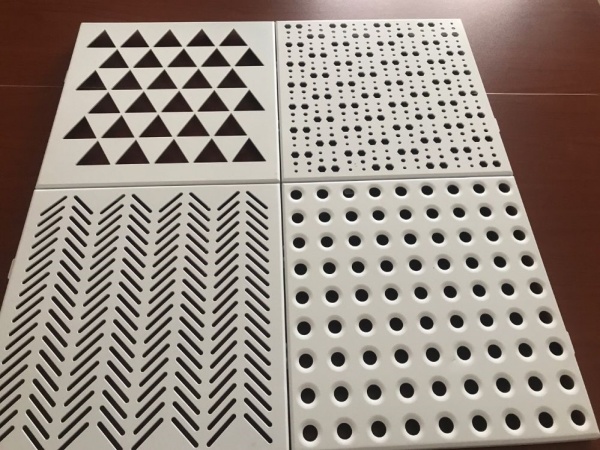

7A09 H36 Punch aluminum plate Punched aluminum plate/Perforated Aluminum plate is made by combining a large number of process steps with computer numerical control (CNC) to punch holes with different spacing on the metal plate, ranging in diameter from less than 1mm to about 500mm. The specification stipulates that the diameter of the hole cannot be smaller than the thickness of the plate. The holes can be arranged in a straight line or in a staggered manner; The cross-sectional shape of a hole can be circular, square, narrow strip, or other irregular forms.

7075 H32 Punch aluminum plate Punched aluminum plate/Perforated Aluminum plate is made by combining a large number of process steps with computer numerical control (CNC) to punch holes with different spacing on the metal plate, ranging in diameter from less than 1mm to about 500mm. The specification stipulates that the diameter of the hole cannot be smaller than the thickness of the plate. The holes can be arranged in a straight line or in a staggered manner; The cross-sectional shape of a hole can be circular, square, narrow strip, or other irregular forms.

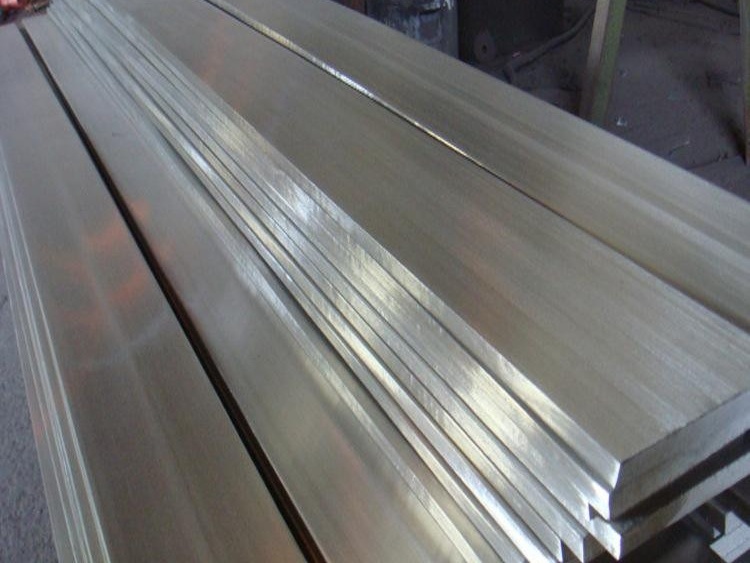

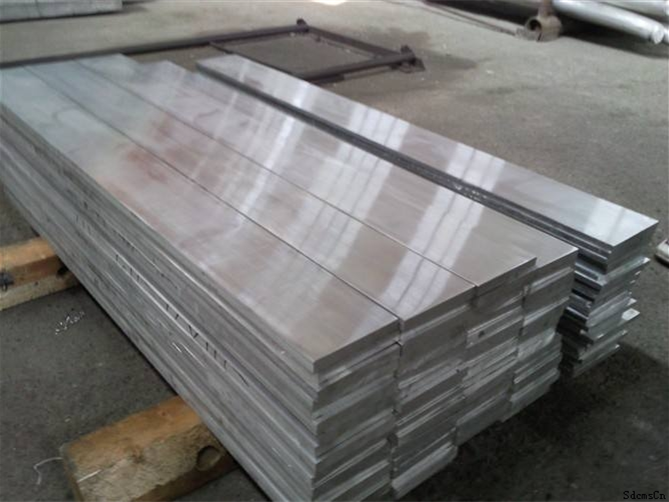

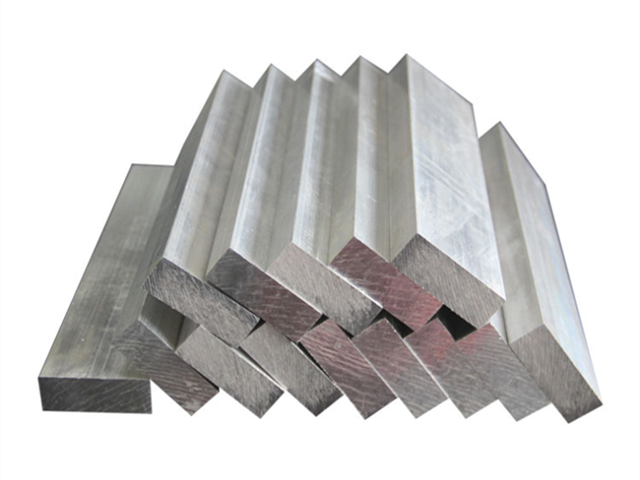

3003 H112 Aluminum flat bar Rectangular aluminum bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

2024 T4 Aluminum flat bar Rectangular aluminum bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

2A06 T4 Aluminum flat bar Rectangular aluminum bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

1200 H24 Aluminum flat bar Rectangular aluminum bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

1100 H112 Aluminum flat bar Rectangular aluminum bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

1080 H18 Aluminum flat bar Rectangular aluminum bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

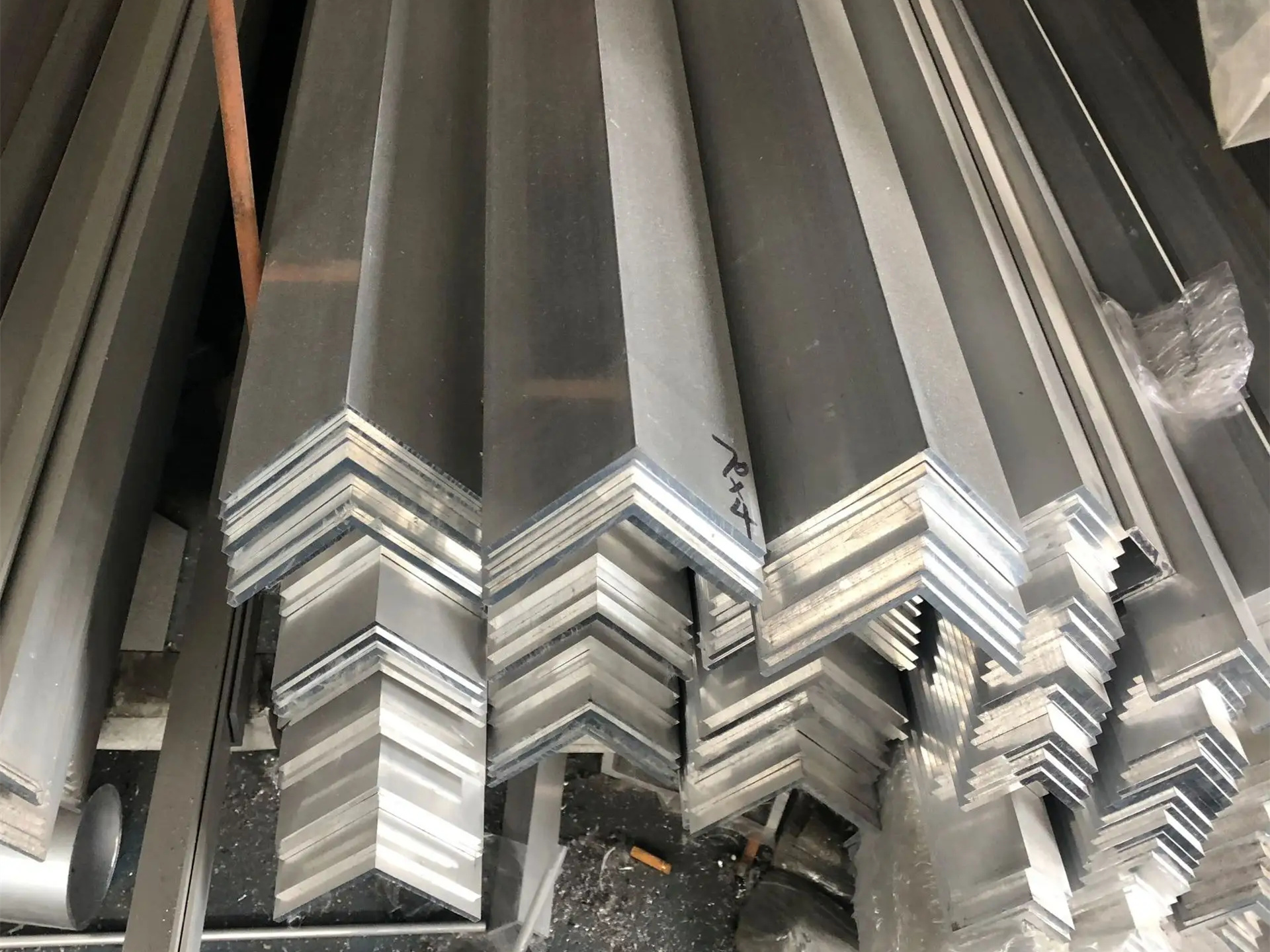

7A09 T6 Angle aluminum Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters

7475 T6 Angle aluminum Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters

7A04 T651 Angle aluminum Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters