PRODUCT CENTER

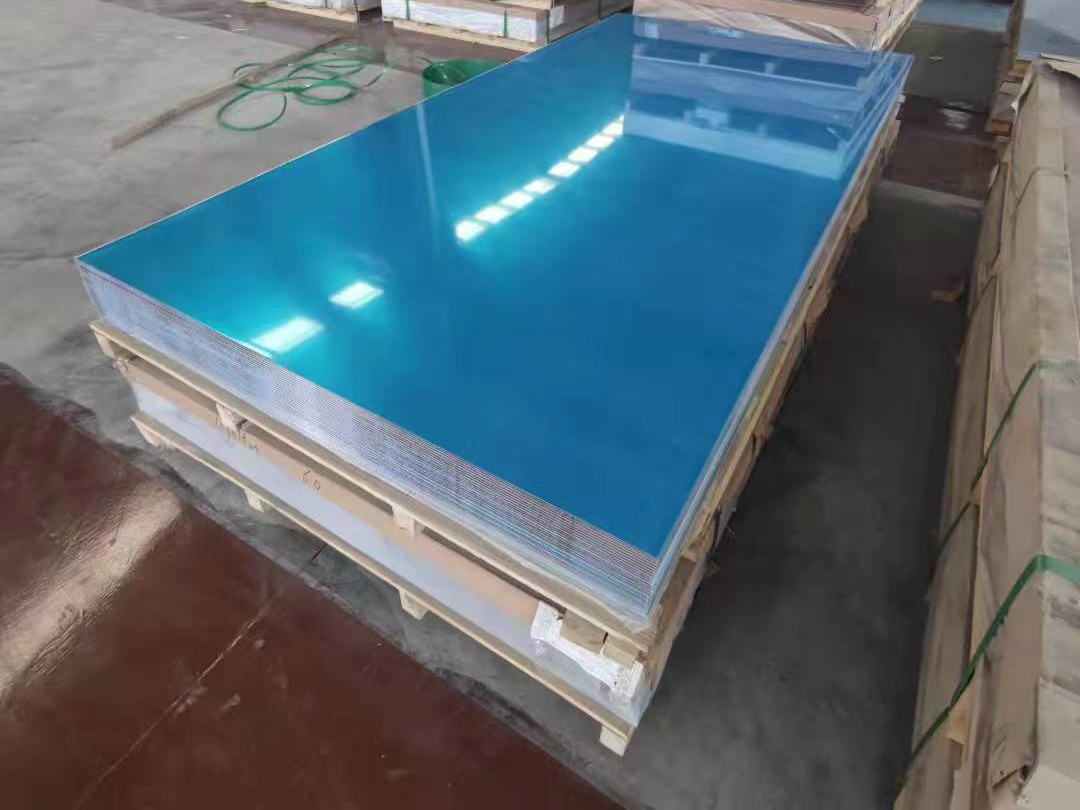

Our company focuses on the hot rolled 1060 O aluminum sheet R & D production, 1060 aluminum sheet has high elongation, tensile strength, excellent electrical conductivity, high formability, can meet the conventional processing requirements (stamping, stretching) requirements.

1, 1060 as a kind of high purity aluminum plate, its melting potential heat, light reflection coefficient is large.

2, the same as 1050 aluminum plate has good electrical conductivity, thermal conductivity, weldability.

3, can meet the conventional processing needs, stamping, stretching, high formability.

4, 1060 alloy aluminum plate has good forming processing characteristics, high corrosion resistance, good weldability and electrical conductivity.

5, mature technology, 1060 aluminum plate price relative to other high-grade alloy aluminum plate has a huge advantage;

6, with the international advanced "1+4" hot rolling line, 450,000 tons of super high production capacity;

7, the product version of the flat, accurate geometric size, at the same time, high surface gloss, alkali washing effect is good, can reach the brush water experiment A level.

1050 O aluminum plate contains more than 99.5% aluminum, is a kind of industrial pure aluminum. 1050 aluminum plate has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity, but the strength is low.

1, 1050 aluminum plate has good forming processing characteristics, high corrosion resistance, good electrical and thermal conductivity;

2. Long service life, low cost, and high recovery value;

3, 1050 aluminum plate processing technology is mature, the price has great advantages compared with other series of alloy aluminum plate;

7005 T6 aluminum plate is super duralumin, good welding performance, heat treatment strengthening, strength is not as good as 6061 aluminum plate, but much lighter, typical lightweight aluminum. It is often used in welding structures with high strength and high fracture toughness, such as vehicle trusses, rods and containers. Large heat exchangers and parts that cannot be fused after welding; It can also be used to make sports equipment such as tennis rackets and softball bats.

The main alloy element of 7050 T6 aluminum plate is zinc. Adding magnesium to the alloy containing 3%-75% zinc can form MgZn2 with remarkable strengthening effect, so that the heat treatment effect of the alloy is much better than that of Al-zinc binary alloy. Mainly used for mold processing, mechanical equipment, fixture, etc., especially for high stress structure requiring high strength, strong corrosion resistance.

7075 T6 aluminum sheet is a cold treatment forged alloy with high strength, 7075 is one of the strongest commercially available alloys. General corrosion resistance, good mechanical properties and anode reaction. The fine grain makes the deep drilling performance better, the tool wear resistance is enhanced, and the thread rolling is different from the weight.

7A04 H112 aluminum plate belongs to Al-Zn-Mg-Cu series of ultra-high strength aluminum alloy, which is commonly used in ultra-duralumin. It is quite mature among ultra-duralumin, and is an alloy used for a long time and a wide range. It has high strength and good heat treatment strengthening effect.

6005 T4 aluminum plate belongs to Al-Mg alloy, which is a kind of rust-proof aluminum widely used. This alloy is widely used, especially in the construction industry. It is a promising alloy, which cannot be strengthened by heat treatment and can be polished.

6060 T4 aluminum alloy, American deformed aluminum and aluminum alloy. 6000 series aluminum alloy features: mainly magnesium and silicon. Mg2Si is the most widely used alloy as the main strengthening phase. Characteristics: Medium strength, good corrosion resistance, good welding performance, good process performance (easy extrusion forming) oxidation and coloring performance.

6082 T4 aluminum plate is an aluminum alloy plate that can be strengthened by heat treatment. It has medium strength, good welding performance and corrosion resistance. It is mainly used in transportation and structural engineering industries. Such as bridges, cranes, roof structures, transport aircraft, transport ships, etc. In recent years, with the rapid development of the shipbuilding industry at home and abroad, reducing the weight of the hull, increasing the speed of the ship, and seeking aluminum alloy materials to replace steel parts have become important issues facing the aluminum processing industry and shipbuilding industry. 6082 aluminum alloy aluminum sheet has medium strength and good corrosion resistance, and is light in weight. It is an ideal material for manufacturing high-speed ship components.

The 5005 aluminum sheet is similar to the 3003 alloy, with medium strength and good corrosion resistance. The anodic oxide film is brighter than the oxide film on 3003 alloy, and is consistent with the tone of 6063 alloy

Our company is a large 5059 H18 aluminum plate manufacturer, producing 1-8 series aluminum plate with foil products. Among them, 5059 aluminum plate is 5 series aluminum alloy plate, which has good corrosion resistance and tensile strength. It is a 5 series product with excellent comprehensive performance, which is widely used in ships, tank cars and other fields, and the market demand is constantly rising.

1, the quality of raw materials, procurement of large manufacturers of aluminum ingot raw materials, from the source to ensure product quality.

2, exquisite processing technology, we have many years of processing experience, mature technology, products through the quality system certification, reliable.

5086 H18 aluminum plate is a typical anti-rust aluminum, 5086 aluminum plate is widely used in need of high corrosion resistance, good weldability and medium strength occasions: such as ships, cars can be weldable parts; Pressure vessel, refrigeration device, TV tower, installation and exploration equipment, transportation equipment, etc. Good weldability and moderate strength, so that it is used in aluminum alloy tank cars, automobiles, ships, high voltage switches, distribution cabinets and other fields.

5182 H18 aluminum plate is often used as a plate for processing can cover, ship side hull plate, deck, car body plate, operating plate, strengthening parts, brackets. Because of its high cost performance, it has been used in batches in many industries, such as automotive interior parts, pull ring material, can tube cover material, refrigeration device, electrical shell, cabinet and other parts.

Our production of 5454 H18 aluminum plate, skilled technology, can adapt to the harsh corrosion environment, is a typical anti-rust aluminum, and high strength, than 5052 aluminum plate about 20% higher. Product quality far beyond the national standards, and to provide the original factory warranty, 5454 aluminum plate in the automobile, aluminum tank car cylinder body and other fields widely used, good reputation.

5754 H18 aluminum plate has good corrosion resistance, excellent processing performance, weldability and easy processing and forming characteristics, we produce 5754 aluminum plate far beyond the national standard, the quality is more reliable. 5754 aluminum alloy plates with different heat treatment states are the main materials used in automobile manufacturing (car doors, molds, seals) and canning industry.

5754 aluminum plate is used in high-speed rail noise barrier, tank car tank material, high-grade alloy doors and Windows, aluminum in the construction field, aluminum in transportation, aluminum in automobiles and other fields.